InComEss Project wrapping-up: What has been accomplished

On February 29th, the InComEss project formally completes its 4-year lifespan, leaving an indelible mark on the landscape of innovation and research on smart materials with energy harvesting and storage capabilities.

As of March 2020, 18 partners from 10 countries united their efforts as core partners of InComEss Project. The project has yielded remarkable results, including more than 17 open-access academic publications and driven some outstanding research on polymer-based smart materials with energy harvesting and storage capabilities in a cost efficient manner for the widespread implementation of the Internet of Things (IoT).

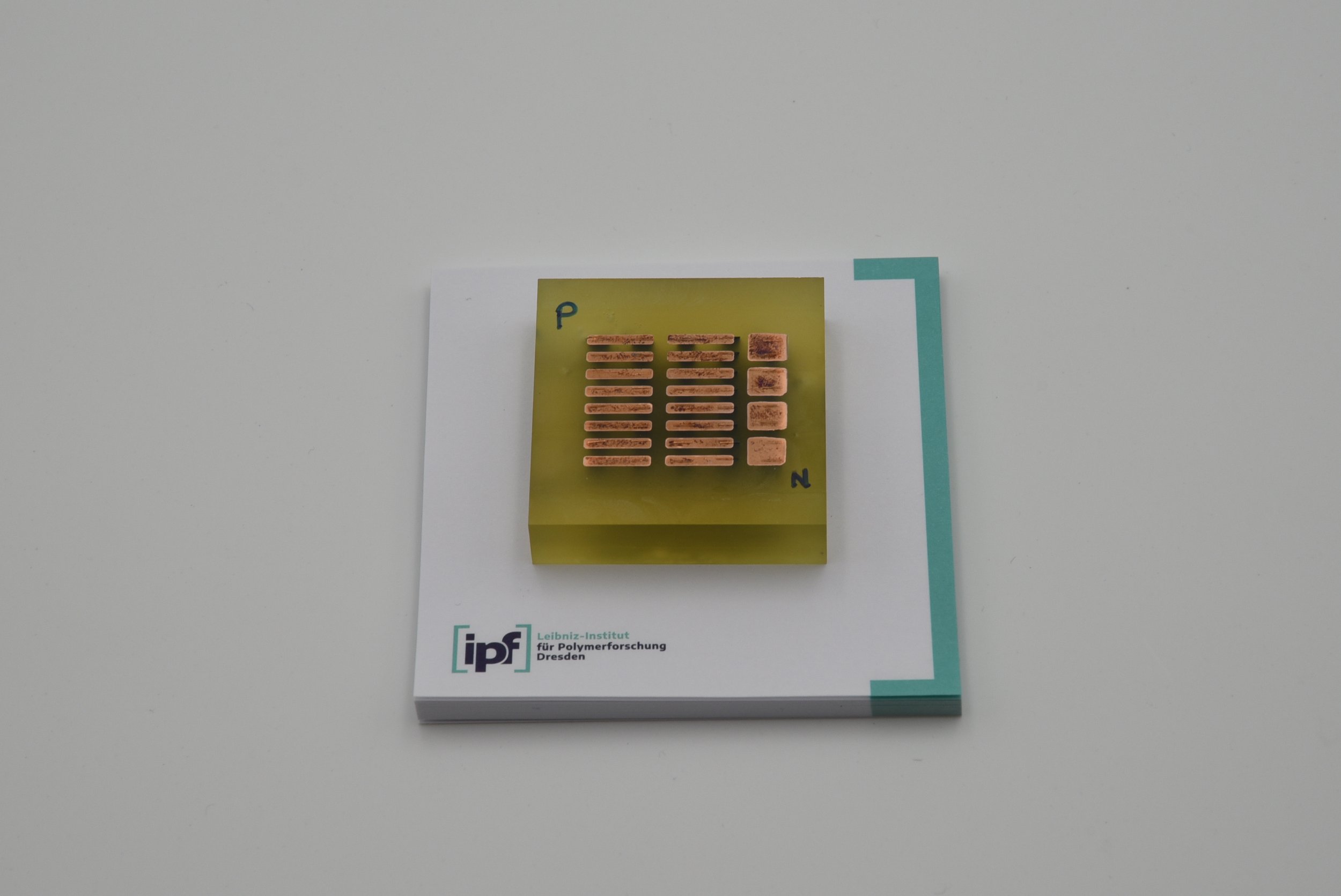

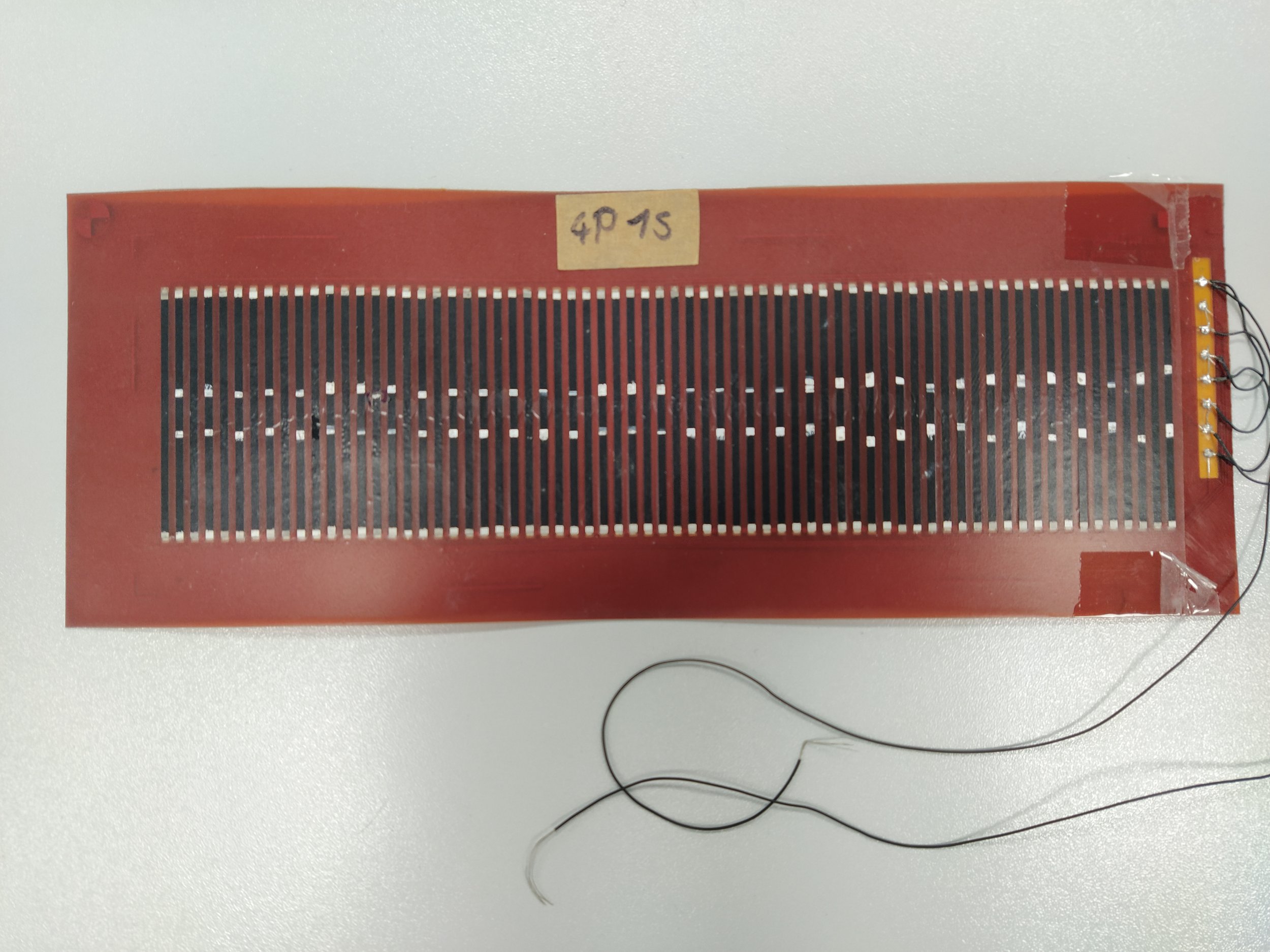

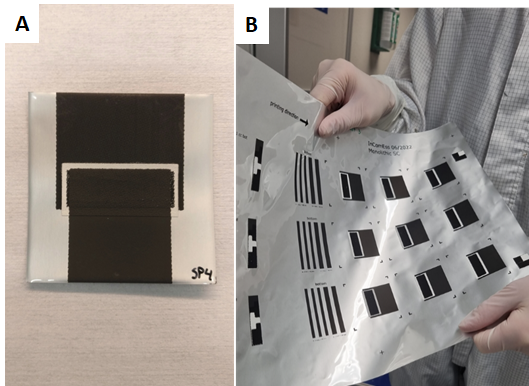

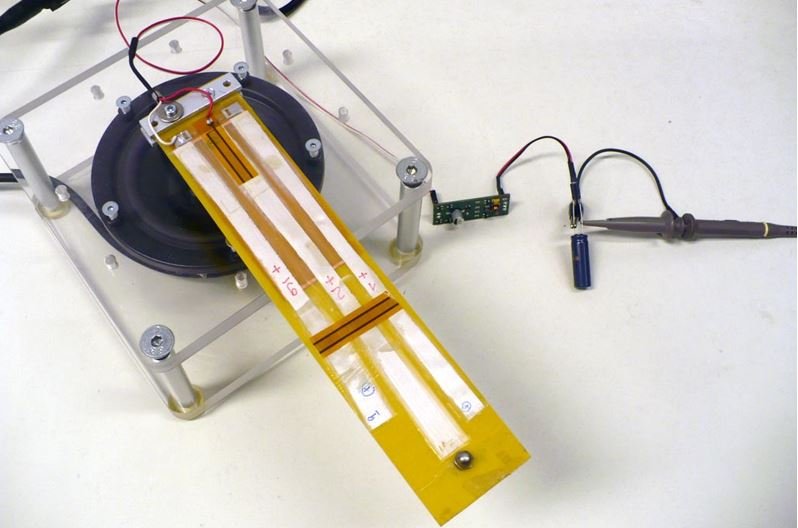

Now after four years of impactful, intensive, and interdisciplinary work from key-experts from across Europe, InComEss is delivering piezoelectric and thermoelectric energy harvesters with a demonstrated ability to generate electricity through mechanical vibrations and temperature differences. The project also saw success in the development of monolithic printed supercapacitors that demonstrated their efficacy to store the harvested energy when integrated with a conditioner circuit and generators.

More achievements include the development of a power conditioning circuit that enhances energy transfer efficiency between generators and end-use electronics. A miniaturized Fibre Optic Sensors (FOS) interrogator with reduced power consumption was showcased for its utility in energy harvesting. Furthermore, the optimization of Bluetooth Wireless MEMS and FOS communications was seamlessly integrated into an IoT platform, offering data monitoring capabilities.

Spotlight on the three-use-cases

Among the research highlights being implemented within InComEss are three impactful use-cases within the aeronautic, automotive, and smart buildings sectors. In the Aeronautic use-case, the tests that were conducted validated the functionality of the Wireless Energy Harvesting Systems (EHS) that were developed over the course of the project. This was achieved by harvesting the available mechanical vibrations of the wing slat (with a lead-based piezoelectric generator) which was able to power the FOS interrogator/Wireless FOS and transmit data to the InComEss IoT platform.

Similarly, the Automotive use-case results demonstrated the reliability of the Wireless EHS. This use-case confirmed the feasibility of harvesting thermal waste from the vehicle's exhaust system to power fuel level sensor nodes and for monitoring the transmission of sensor data via Bluetooth to the InComEss IoT platform.

The smart building use-case demonstrated the potential to include FBG in a façade envelope for Structural Health Monitoring. However, challenges were encountered during the piezoelectric generators' tests, which included exposure to impact, rain, and wind. Unfortunately, the power output from these generators proved insufficient for sustaining the conditioner and electronics, marking a notable aspect for further refinement and development.

Looking forwards

As InComEss concludes its four-year journey, it leaves a legacy of innovation, collaboration, and significant advancements in the realm of smart materials and innovative energy harvesting systems.